Space

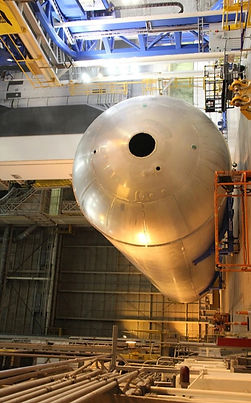

Rockets and spacecrafts endure extreme heat, erosion, and micro-debris impacts, resulting in costly refurbishments per launch.

Our novel materials extend the lifecycle of critical components by resisting thermal shock, oxidation, and certain orbital impacts - enhancing spacecraft survivability, lowering costs per launch, and driving rapid reusability.

Visual shown is a conceptual application demonstration

-

Safeguards propellant tanks, feedlines, and valves from cryogenic cycling, liquid fuel exposure, and hydrogen-induced cracking.

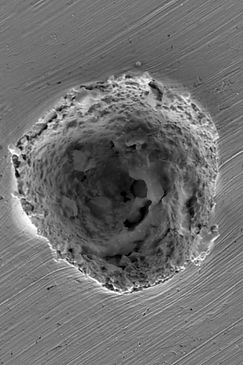

Ablation

& Surface Erosion

-

Extends life of rocket fairings, and structual joints by resisting ablation, plasma erosion, and gas shear effects.

Micrometeoroid & Debris Impact

-

Shields satellite structures and spacecraft hulls from high-velocity particle strikes and small orbital debris penetration.

Thermal Fatigue & Oxidation

-

Protects cryogenic tanks, valves, and feedlines from repeated chill–heat cycles and oxidative stress during launch and re-entry.

Space Applications

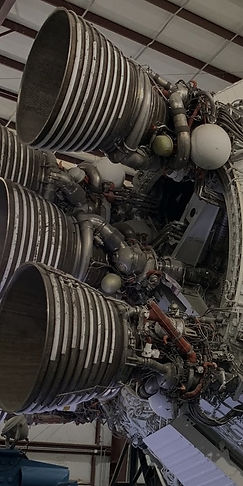

Propulsion & Power Systems

-

Engine Throat Wear Layers (outer protective coat only)

-

Turbopump Bearings, Shafts & Housings

-

Fuel Injectors & Injector Plates

-

Cryogenic Pump Impellers & Valve Components

-

Power Generation Turbines

-

Electric Propulsion Thruster Components

Thermal Protection & Structures

-

Fuselage / Outer Hull Micrometeoroid Shielding

-

Structural Joints & Fasteners (thermal cycling & oxidation control)

-

Internal Tank Surfaces (thermal fatigue resistance)

-

Secondary Frames & Load-Bearing Members (oxidation/erosion resistance)

Orbital & Control Systems

-

Satellite Thruster Components (cold-gas, monoprop, biprop)

-

Reaction Wheel Bearings & Housings

-

Solar Array Hinges & Deployment Mechanisms

-

Attitude Control System Valves & Actuators

-

Antenna / Sensor Gimbal Bearings

Fuel & Fluid Systems

-

Cryogenic Tank Linings (LOX, LH₂, CH₄)

-

High-Pressure Lines & Fittings

-

Pump & Valve Internals (propellant feed systems)

-

Manifolds & Distribution Blocks

-

Heat Exchanger Surfaces (fuel preburner loops)

Environmental & Survivability

-

Micrometeoroid & Orbital Debris Shields (sacrificial outer layers)

-

Anti-oxidation Coatings for Long-Duration Orbits (LEO/GEO)

-

Radiation-Resistant Coatings for Electronics Housings

-

Thermal Radiator Panels (oxidation & atomic oxygen resistance)

-

Protective Coatings for Docking Mechanisms

Get Involved

Engage with Mjolner today by requesting a sample.

Spacecraft : Micrometeoroid impact (2-3mm 7km/s), Immunity to Particle impact

Landing Gear & Structural Joints (Reusable Boosters) : Fatigue resistance +40%, Refurbishment time reduction +25%

Reaction Wheels & Bearings : Component life +40%, Reduced in-orbit failures +30%

Fuel Pump & Valve Internals (Cryogenic) : Reliability +40%, Overhaul cycle extension +30%

Re-entry Heat Shields (non-thrust surfaces) : Thermal shock resistance +25%, Crack/erosion prevention +20%

Payload Bay & Fairing Liners : Erosion resistance +30%, Cleaning/turnaround time reduction +25%

"Performance data represents estimated ROIs based on publicly available sources and benchmark studies. Actual results will vary on a case-by-case basis."

Application Methods - The Process

Our Tailored Coating Process

-

You Define the Mission: Tell us your component and performance requirements.

-

We Engineer & Sample: We customize material formulations & methods and deliver test samples.

-

You Validate: Run your application-specific tests; if needed, we refine the formulation.

-

We Finalize & Deliver: Lock in coating methods, process your parts, and share the performance data.

We are here to Precisely Tuned to Your Needs.

Thermal Spray

Cold Spray

HVOF/HVAF