DEFENCE

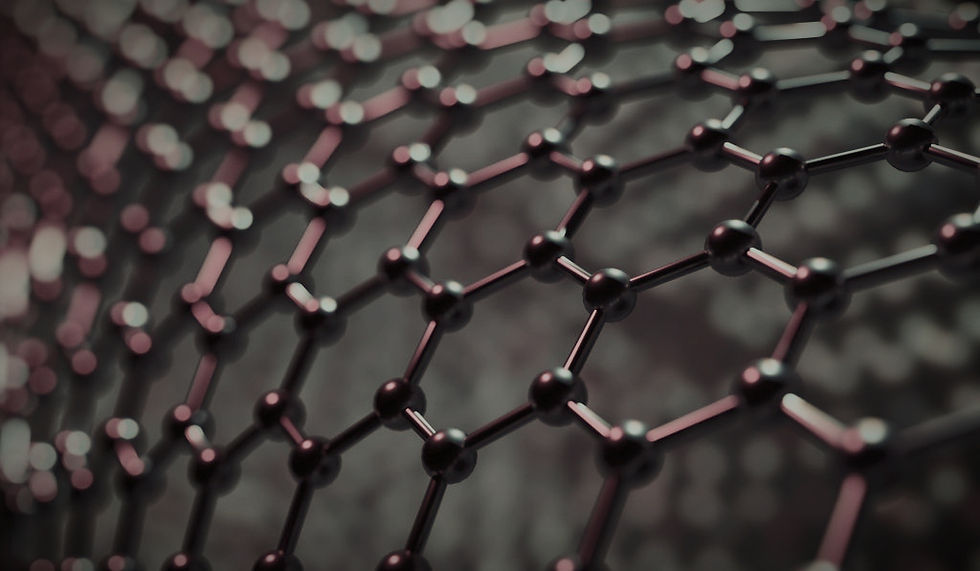

Our proprietary nano-gradient architecture integrates metallic and ceramic phases in a continuous, graded structure. This eliminates weak interfaces found in conventional coatings, drastically improving impact resistance, corrosion & oxidation resistance, abrasion & thermal tolerance, adhesion, and lifespan. It is the same core technology that underpins our ballistic armour, now adapted for non-ballistic performance enhancement.

Built for extreme conditions, our technologies ensures maximum reliability, reduced maintenance, and sustained mission readiness across land, air, and sea platforms.

Visual shown is a conceptual application demonstration

Extends operational life of engines, drivetrains, and weapon systems while reducing maintenance demands in all climates.

Increases durability of turbines, compressors, and rotor systems by preventing erosion, oxidation, and structural fatigue.

Protects propulsion and launch systems from cavitation, corrosion, and erosion, ensuring sustained fleet readiness.

_edited_edited_p.png)

Contact Us

Discover how Mjolner’s Technologies can Strengthen your Capability and Support Mission Success.

Nano-gradient metal-ceramic coatings transition from a tough, metal-rich bond layer to a hard, ceramic-rich surface, removing the weak interface that causes traditional coatings to crack, spall, or delaminate.

This architecture delivers high hardness for wear, erosion, and corrosion resistance, while the ductile base absorbs impact and survives extreme thermal cycling.

In defence applications, it extends service life by 1.5-3x and reducing maintenance downtime by up to 50%.

Unlike monolithic ceramics or brittle PVD films, our coating disperses shock, blocks corrosive ingress, and maintains adhesion under repeated impact and high temperature - making it a force multiplier for land, naval, and air platforms.