Industrial

Defence-Built. Industry-Ready.

We bring next-generation advanced materials and expertise into the heart of global industry. Born from defence and ballistic engineering, our proprietary composites and coatings deliver unmatched impact resistance, thermal stability, and corrosion immunity - without adding cost over traditional materials.

Designed to survive the world’s most extreme conditions, our technologies is ready to transform performance and uptime across oil & gas, mining, heavy manufacturing, automotive production, space systems, aviation, and maritime logistics. We outlast and outperform conventional materials - extending service life, reducing downtime, and redefining operational efficiency in every sector we enter.

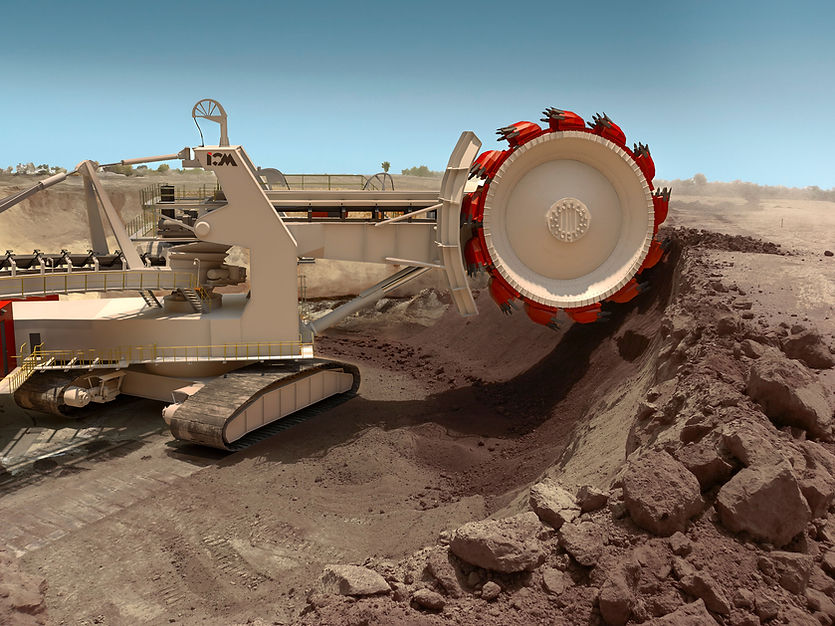

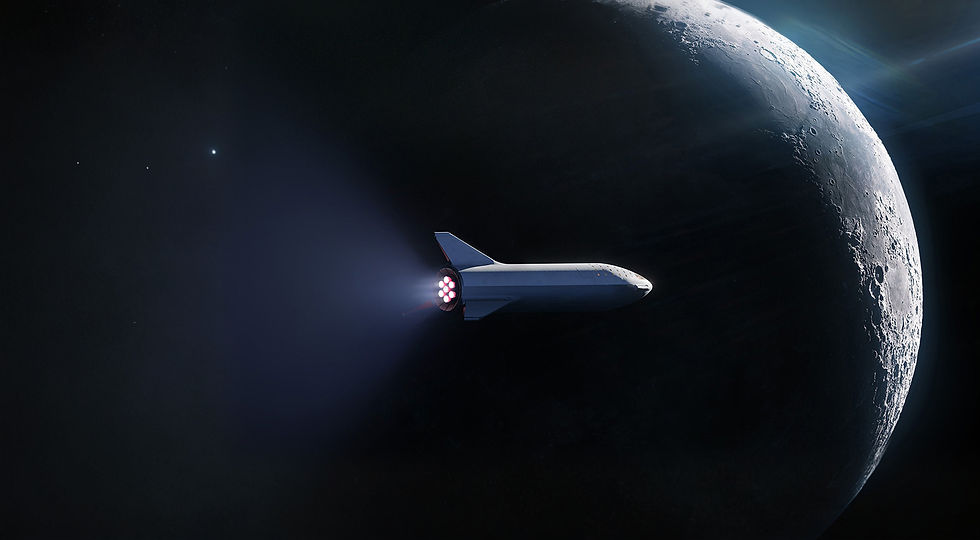

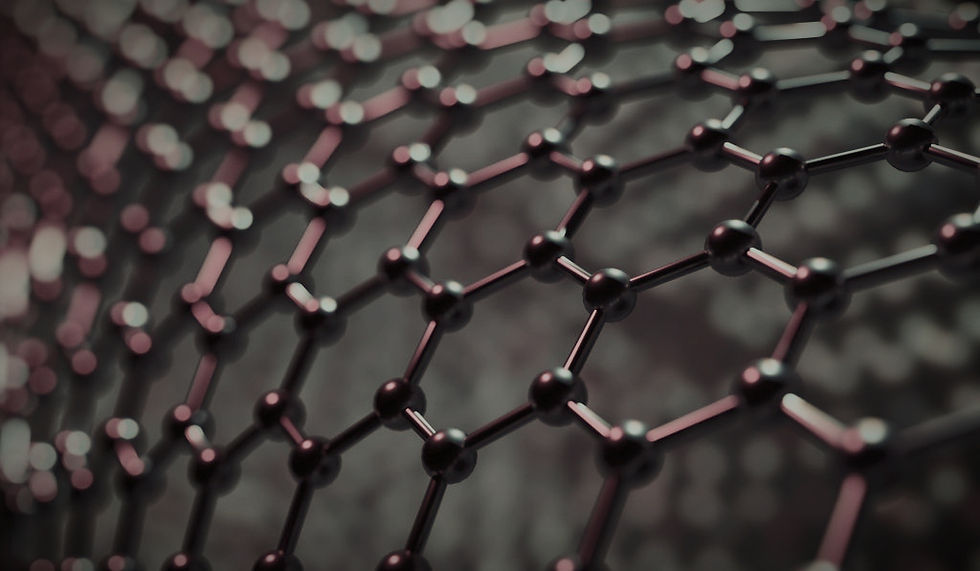

Visual shown is a conceptual application demonstration

Revolutionising uptime and durability in drilling, pumping, and refining with our material technologies.

Extending machinery life and reducing downtime through unmatched resistance to impact, abrasion, and heat damage.

_edited_edited_.png)

_edited_edited_.png)

Enhances vehicle performance and longevity by protecting critical components from wear, heat, and corrosion.

Protecting engines, landing gear, and aerodynamic surfaces from erosion, heat stress, and corrosion - delivering safer, more reliable long-haul performance.

Reducing maintenance and repair costs by preventing corrosion, cavitation, and impact damage to propulsion and deck systems.

Extends mission hardware lifespan, reduces refurbishment cycles, and lowers per-launch costs - advancing the goal of rapid reusability.

Biomedical (Awaiting Validation)

_edited_edited_.png)

Our coatings show future potential in biomedical engineering, where their durability and corrosion resistance could enhance implants and surgical tools - pending biocompatibility validation.

_edited_edited_p.png)

Contact Us

Learn how Mjolner’s innovations are transforming industrial performance - delivering longer uptime, lower cost, and uncompromising reliability.

Mjolner’s nano-gradient coatings, bulky Al-Ti composites, and amorphous alloys unite hardness, ductility, and thermal stability in one architecture - eliminating the weak points that cause traditional coatings to fail.

Backed by decades of materials expertise, we tune every solution to exact performance standards. Alongside our proprietary platforms, we also offer traditional ceramics and industry coatings - balancing durability, cost, and compatibility for your specific application.

The result: More ROI, not more cost. Our technologies deliver 2-4x longer service life, 30-50% less downtime, and lower total ownership costs - all while offering competitive pricing.

Across energy, mining, automotive, aviation, space, and maritime logistics, Mjolner turns protection into economics: more value per machine hour, per ton mined, per flight hour, and per voyage.