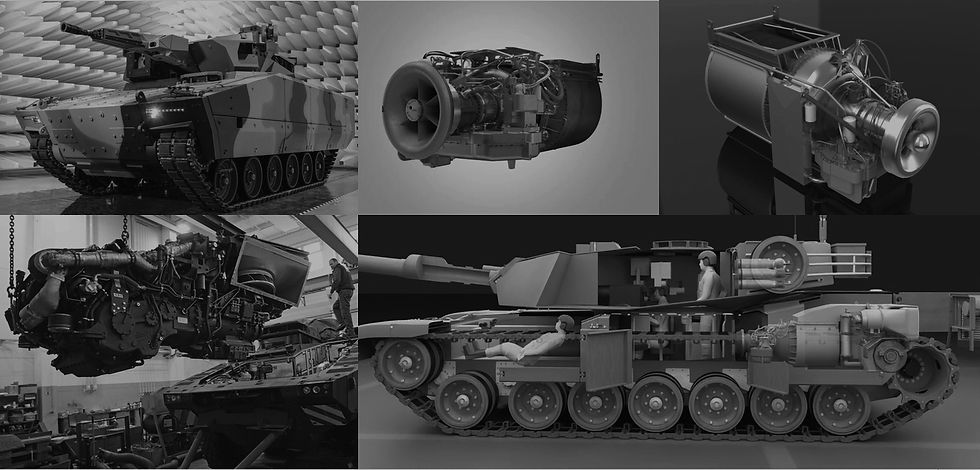

Land Systems

Land platforms operate in extreme theatres where grit abrasion, corrosive moisture, and high thermal loads rapidly degrade mission-critical systems.

Our nano-gradient coatings provide superior mechanical and chemical protection, shielding hulls, drivetrains, and exposed components from premature failure. The result: extended service intervals, reduced sustainment logistics, and maximum combat availability - even in the harshest operational conditions.

Visual shown is a conceptual application demonstration

-

Extends service life of gears, shafts, and driveline components under high-load, abrasive conditions

Corrosion

& Oxidation

-

Protects against rust, water, chemicals and high-heat oxidation

Mechanical Fatigue

-

Superior shock tolerance reduces microcracking and part fatigue

Thermal Stability

-

Retains mechanical integrity through rapid thermal cycling

Wear Resistance

-

Nano-gradient structure withstands severe abrasion from sand, grit, and high-load contact surfaces. Shields gears, shafts, and driveline components from scoring and fatigue, extending operational life in all theatres and conditions.

Corrosion & Oxidation Resistance

-

Multi-layer metal-ceramic barrier blocks moisture, de-icing agents, hydraulic fluids, and thermal oxidation. Prevents pitting, rust propagation, and scaling that compromise mechanical integrity.

Impact Absorption

-

Graded composition disperses shock from heavy impacts and torsional loads, reducing the onset of microcracks, spalling, and structural fatigue.

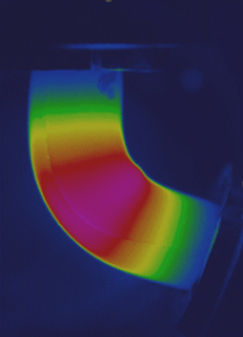

Thermal Stability

-

Maintains performance under sustained temperatures without structural breakdown or loss of adhesion - especially in high-impact, high-erosion zones where monolithic ceramics often suffer brittle fracture under combined thermal and mechanical loading.

Land Systems Applications

Engines & Transmissions

-

Protects turbine parts, gear sets, bearings, and shafts from galling and abrasive wear, ensuring operational continuity well beyond standard service intervals.

Suspension & Steering Systems

-

Shields kingpins, tie rods, ball joints, and pivot points from pitting, corrosion, and deformation under heavy load.

Hydraulic Systems

-

Preserves sealing surfaces on cylinder rods and pistons, maintaining fluid integrity in grit-heavy or mud-laden environments.

Tracks & Driveline Components

-

Reduces wear from sand, rock, and debris ingress, preventing premature failure and loss of mobility.

Turret Bearing Races

-

Coating prevents galling, pitting, and wear from the immense rotational loads and shock impulses of large-calibre firing. Maintains smooth traverse performance under sand, dust, and salt exposure.

Gun Barrels (MBT/SPG)

-

Enhances barrel liner durability against thermal cracking, erosion, and propellant gas wear. Extends barrel life, preserves rifling geometry, and delays re-lining or replacement.

Track Pads & Road Wheels : Pad life +80%

Turret Bearing Races : +40% MTBF

Brake System Components : +20% Caliper life

Engine Internals/ Hydraulic : Extend engine life +30%, Valve life +60%, Wheel service life +70%

Suspension & Steering Linkages : Component life +50%

Transmission & Drivetrain : +50% Service Interval

"Performance data represents estimated ROIs based on publicly available sources and benchmark studies. Actual results will vary on a case-by-case basis."

Application Methods - The Process

Our Tailored Coating Process

-

You Define the Mission: Tell us your component and performance requirements.

-

We Engineer & Sample: We customize material formulations & methods and deliver test samples.

-

You Validate: Run your application-specific tests; if needed, we refine the formulation.

-

We Finalize & Deliver: Lock in coating methods, process your parts, and share the performance data.

We are here to Precisely Tuned to Your Needs.

Thermal Spray

Cold Spray

HVOF/HVAF