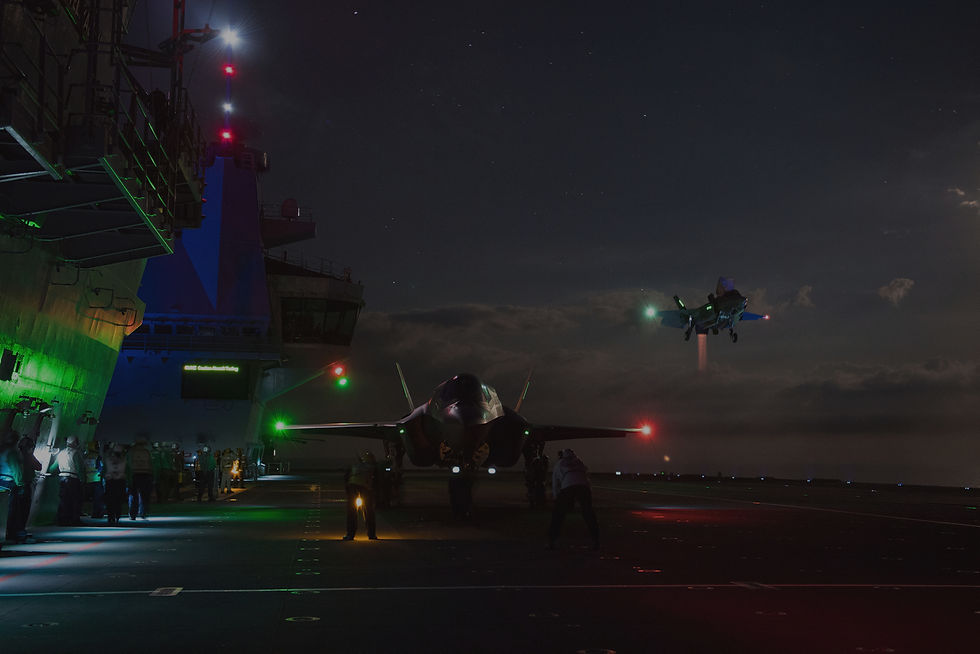

Aviation Systems

Across supersonic fighters, strategic airlifters, and rotary-wing platforms, airborne assets faces extreme operational stress - micro-impact from particles, rapid thermal cycling from high-altitude transitions, and constant vibration from sustained flight.

Our novel technologies protect airframes, propulsion assemblies, and mission systems against wear, corrosion, and thermal degradation without imposing weight penalties. We ensure aircrafts peak readiness across the most demanding operational environments.

Visual shown is a conceptual application demonstration

Enhancing Aircraft Life-Cycle

-

Exceptional erosion resistance shields blades and surfaces from sand, rain, and debris

Corrosion

-

Unmatched protection for compressor and turbine components against fuel residues and moisture

Mechanical Fatigue

-

Reduces microcracking, spalling, and fatigue under repeated high-load stresse

Thermal Stress & Oxidation

-

Stable performance under heat cycles, preventing oxidation, scaling, and thermal fatigue.

Wear & Erosion Resistance

-

Nano-gradient architecture disperses abrasion from sand, dust, rain, and airborne particles. Preserves wing leading edges, engine inlets, and rotor blades from aerodynamic surface loss

Corrosion Protection

-

Seals underlying material against fuel, hydraulic fluid, chemicals, and atmospheric moisture. Prevents pitting and galvanic corrosion on airframe structures and landing gear assemblies.

Mechanical Fatigue Mitigation

-

Layered composition diffuses cyclic stresses from sustained high-G manoeuvres, turbulence, and repeated pressurisation cycles. Slows crack propagation in spars, rotor hubs, and structural joints.

Thermal Stress & Oxidation

-

Withstands sustained heat and shields against oxidation, scaling, and adhesion loss in exhaust ducts, hot-section panels, and fasteners.

Aircraft Applications

Compressor Blades & Disks

Resists wear and oxidation from airborne particulates, extending time-on-wing and reducing hot-section replacements.

Wing & Tail & Blade Leading Edges

Shields against sand, rain, and debris impacts, maintaining aerodynamic shape and maximising lift efficiency in high-erosion environments.

Turbine Blades

Forms a high-temp thermal-erosion barrier, improved sortie rates and longer TBC lifespan.

Landing-Gear Struts & Actuators

Seals out corrosive fluids and salt-laden air while absorbing high-energy landing shocks - preventing pitting, deformation, and joint seizure.

Gearbox Gears

Prevents micro-pitting and lubricant-borne abrasion under heavy torque, extending gear life and significantly lengthening rebuild intervals.

Tail-Rotor Drive Shafts

Resists torsional fatigue and microcracking while sealing out salt, moisture, and thermal cycling damage - slowing wear, maintaining torque transfer, and extending service life.

Compressor Blades & Disks : +30% TBO

Wing & Tail Leading Edges : -20% A-check downtime

Turbine Blades : 2× TBC lifespan

Landing-Gear Struts & Actuators : 2× MRO Intervals

Gearbox Gears : +40% MTBF

Drive Shafts : -60% Shaft rebuilds

Tail-Rotor Drive Shafts : 2× Interval

Main-Rotor Mast Bearings : +50% Bearing life

Pitot-Static Tubes & Probes/APU Vent : -80% Probe replacements

"Performance data represents estimated ROIs based on publicly available sources and benchmark studies. Actual results will vary on a case-by-case basis."

Application Methods - The Process

Our Tailored Coating Process

-

You Define the Mission: Tell us your component and performance requirements.

-

We Engineer & Sample: We customize material formulations & methods and deliver test samples.

-

You Validate: Run your application-specific tests; if needed, we refine the formulation.

-

We Finalize & Deliver: Lock in coating methods, process your parts, and share the performance data.

We are here to Precisely Tuned to Your Needs.

Thermal Spray

Cold Spray

HVOF/HVAF